Project Overview

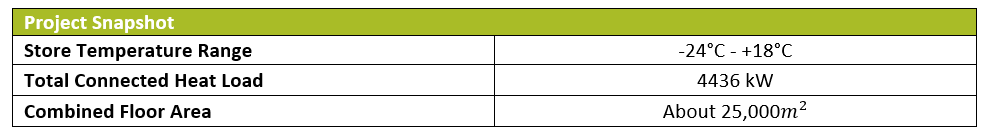

The first of its kind in Australia, Oomiak was engaged by a leading supermarket chain to provide a refrigeration solution for their new Customer Fulfilment Centre (CFC) in New South Wales.

The refrigerated CFC is a specialised coldstore designed to handle and fulfill online orders for perishable products such as fresh produce, dairy products, meat, and frozen foods. Products are received, sorted, and stored in temperature-controlled areas until they are picked and packed for delivery. The new CFC is highly automated, using robotics, conveyor systems, and other technologies to streamline the order fulfillment process.

The refrigerated CFC operates much like a traditional CFC, with the added complexity of managing temperature-controlled storage and handling of products. The CFC is divided into different temperature zones to accommodate different types of products and their specific temperature requirements.

The Refrigeration Scope:

Helping bring this to life, Oomiak facilitated the refrigeration works and understanding the unique requirements of the project was an important key to our success. Our team analysed the critical project requirements, key objectives, input data provided, and the brief provided to create a tailored solution.

Some musts that were required:

- Maximised operational efficiency

- Reliability

- Flexibility to cater to future operations and expansions

Catering to this, we executed a two-stage plant with three temperatures featuring a low charge Ammonia refrigeration system utilising multiple screw compressors. Incorporating energy-efficient technologies and benefits was key in this project.

Using smart thinking Oomiak were able to produce a creative and custom refrigeration solution that satisfied all parties.

Get in touch to see what our team can do for you – or call us on 1300 731 699.